Based largely on Building an Active Fog Distribution System by Richard Cadena.

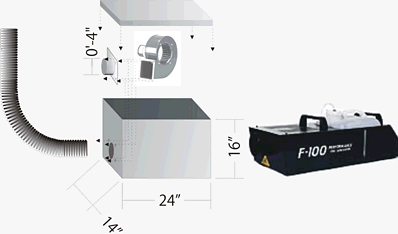

A smoke ducting system consists of one or more smoke machines, and some ducting, if it is an "active" system it also includes an air blower. The blower is usually contained in a metal fabricated housing the Distribution Box or Expansion Box. In an active system, the smoke machine can be directed into the intake side of the expansion box without any ducting at all. An expansion box may have (as ours does) a 4" flange on the output side that couples with a 4" duct. The intake side has an open 4" port without a flange that draws smoke from the output of the smoke machine. The suction from the air blower is sufficient to draw all the smoke that the smoke machine can deliver without being coupled directly to the expansion box. The expansion box is large enough to act as a smoke reservoir. From the expansion box, the ducting is routed from the output of the box throughout the area to be covered with smoke. An illustration showing the basic components of an active smoke ducting system is at right.

An excellent material to use for smoke ducting is ADS drainage hose (Advanced Drainage Systems, Columbus, Ohio, 800/733-7473). ADS is a durable, flexible, ribbed 4" hose normally used for irrigation and drainage systems. It easily attaches to other components with RTV silicon rubber. There are several fittings made by ADS, like couplers, "T" fittings, 90 degree fittings, end caps, etc., that can be used to design complex ducting systems. ADS hose is very reasonably priced and usually easy to find. It is normally stocked in nursery supply outlets and retail hardware and lumber stores in most metropolitan areas of the United States. Other types of ducting: Larger diameter ducts provide less resistance to the flow of smoke and are recommended for large volumes of smoke and/or a long run of duct, dryer hose is not recommended, it is not nearly as durable as ADS. A good smoke expansion design should take into consideration the airflow of the room... the location of the air conditioning registers. The smoke should be discharged at a location farthest away from the air conditioning intake for maximum smoke effectiveness.

The air conditioning registers (output) will tend to stir up and dissipate the smoke. The ducting may be branched off in order to deliver smoke to different locations. A duct may extend one or two hundred feet or more provided the proper air blower is used. The longer the run is, the longer the delay will be between enabling the smoke machine and the delivery of the smoke. Typically, a one hundred foot tube (duct) will take a few seconds for the smoke to come out. Under normal circumstances, a large volume of smoke will pour out of the end of the ducting even if the ducting is perforated.

Delivering Smoke to various locations

Perforations in the ducting help deliver smoke if it is needed along the route of the ducting, rather than dumping the entire contents out of the end of the duct. A perforated tube acts much like a sprinkler system for smoke. ADS ducting is durable, yet lightweight enough to be easily perforated with a pocketknife or a cordless drill. A drill bit makes a big enough perforation to deliver smoke, the bigger the hole the more smoke at that location. It's best to start with an unperforated tube. Turn on the system and begin perforating, then examine the results to see if more perforations are needed and if the perforations are delivering the proper amount of smoke to the proper locations. Keep in mind that each perforation causes a slight drop in pressure along the length of the tube. Therefore, the perforations should be larger in diameter and greater in number farther away from the air blower to get the same volume of smoke at the end. The end of the ducting can be capped to help maintain pressure along the entire length of the tube.

Over time, smoke fluid will tend to condense inside the ducting because it cools as it is being delivered. ADS is ribbed, so the excess smoke fluid will collect in the ribbing. However, if the ducting is installed in a sloping fashion, gravity will cause the fluid to drip through perforations, if perforated. Therefore, it is best to design the slope towards the blower in order to force the excess smoke fluid to collect in the expansion box rather than on the floor. In a fixed installation, it is recommended that every year or so, you check and drain the expansion box.

American Safety ASHP (1-888-BUY-ASHP, www.buyashp.com) markets an expansion box tailor made for permanent installations. It is constructed of galvanized aluminum and is supplied with a 4" flange for coupling to ADS. The air blower is a squirrel-cage fan that delivers 495 cubic feet per minute under no-load conditions. It can be ordered for 115V at 50/60 Hz or for 230V at 50/60 Hz operations. The blower mounts on the inside of the expansion box with four bolts. The mounting holes are pre-drilled in the expansion box for convenience. To assemble the expansion box simply insert the flange from the inside of the box using RTV silicon to form a seal between the box and the flange, then place the flange of the air blower over the expansion box flange and bolt in place. The inside of the expansion box is easy to access because the entire lid is a separate piece that can be removed without the use of tools.

Once the air blower is mounted, it must be wired to the mains supply. A good method of wiring it is to use a Greenlee punch and punch a hole in the sheet metal large enough to mount a junction box. Then, conduit can be run to the junction box and back to the relay panel or other switching device (such as an ordinary light switch). The blower draws about 3.25 amps and medium size smoke generator draws about 14 amps at 115VAC. They can both be supplied from the same 20-amp circuit provided there are no applicable de-rating factors (in the United States, refer to the National Electrical Code or to local regulations). The dimensions of our smoke expansion box are given in the diagram for reference.

Once the system is installed and the electrical connections made, the smoke machine and the air blower can be powered up at the same time and kept on continuously. One of the advantages of building a smoke distribution system is that it allows the smoke machine to be located in an area with convenient access for changing fluid containers and for maintenance. Avoid locating a smoke machine over people's heads or directed at a high traffic area with a smooth floor, it can get slippery. Smoke machines produce very hot particulate that could spew onto someone. It's also a lot more difficult to service a smoke machine on a ladder than in an electrical closet. By using a distribution/expansion system, the smoke machine may be located in the most convenient place.